The United States is home to over 30 million small businesses. Having success as a small business owner will require perseverance and a laser focus on operational efficiencies.

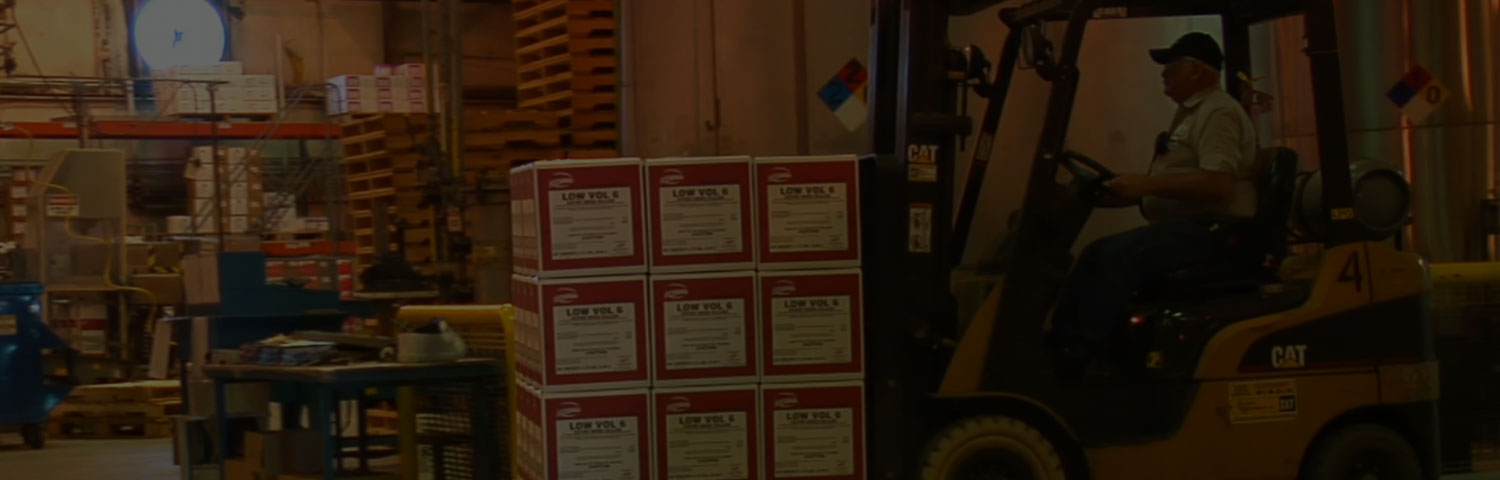

If your business operates a warehouse, finding ways to make it more efficient is a must. Using the right technology and procedures can increase productivity levels. Greater productivity levels in your warehouse will have a direct impact on your bottom line.

While most warehouse-based companies realize the need for optimizing efficiency, they have problems knowing where to start. Working with professionals who are familiar with warehouse operations is usually a step in the right direction. With their help and guidance, achieving your goals will be much more certain.

The following are some of the things you need to consider when trying to improve warehouse operations.

1. Mobile Technology Can Improve Warehouse Operations

Trying to enter in inventory or track shipments manually is highly inefficient. Business owners who refuse to embrace the power of technology will lose their competitive edge. Embracing technology will reduce the cost of human error.

There are a variety of mobile computers designed for use in warehouses. Their features include barcode scanners and RFID readers.

With these systems, your workers will be able to scan incoming shipments of products in record time. The cost of these mobile computers is worth the investment considering the increased productivity levels and overall accuracy they provide.

2. Transparency and Information Visibility Work Hand in Hand

One of your main concerns when trying to improve warehouse operations is making the sharing of information easier for your team. Your infrastructure will need to allow employees to share information about shipments, inventory, and a host of other important data with the click of a button.

If the current data collection and transfer method you have includes pen and paper, now is the time to make a change. Modernizing data collection using software programs is a good idea.

Most of the data systems used by modern warehouses are cloud-based. This means that the information put on these programs will be backed up and stored in an instant. If you ever experience a network crash or other mishap, you can access the data on the cloud.

3. A Warehouse Management System Is a Must

Keeping up with inventory control, shipping costs, and order fulfillment can be overwhelming for a business owner. Instead of letting stress overtake your life, you need to look for modern solutions to your problem.

The best way to deal with these challenges is to invest in a warehouse management system. Modern warehouse management systems are designed to make businesses more efficient.

If you combine the use of a warehouse management system with the technology mentioned above, you will notice a big difference in how productive your team is. Consulting with technology professionals will help you figure out which software program is the right fit.

4. Locating Products Is Much Easier with Organized Bins

As any warehouse-based business owner knows, getting orders pulled and filled quickly is the key to success. If your warehouse lacks organization and is in a state of disarray, it will be impossible for employees to find and fill orders fast.

The first thing you should consider when trying to fix these issues is bin placement. A comprehensive distribution software program will allow you to quickly locate your inventory.

While it will take some time and effort to scan all of the merchandise into this system, it will be worth it in the long run. When used correctly, distribution software reduces the work your team has to invest to fill an order. This means they will be faster and more efficient.

5. Keep Track of Inventory Picking

Every square inch of space in a warehouse must be used efficiently. Rather than stocking products that are simply not selling, you need to track inventory picking closely.

Adequately recording the number of times a particular product is picked is beneficial. With this information, you can decide whether or not an item needs to be taken out of inventory.

By taking the optimization of your inventory seriously, profits will grow. Failing to assess this important information will lead to wasting a lot of valuable space in your warehouse. Over time, constant inventory optimization will become easier and more accurate.

6. Use Electronic Advanced Shipping Notifications (ASN’s)

Modern warehouse-based businesses can get in a lot of trouble when relying on traditional shipping and receiving schedules. Most times, relying on these traditional schedules will lead to inefficiency in your warehouse.

Using electronic Advanced Shipping Notifications can help you plan out how much manpower you need to handle certain shipments. Not only does this reduce labor costs over time, but it can also make your team more productive and keep your costs down.

Before choosing a program to help with this task, you need to do your homework. Selecting an electronic advanced shipping system that is easy to use and effective should be your main goal. Allowing professionals to set up this system can help you reduce the mistakes made during implementation.

Let Professionals Lend You a Hand

Are you finding it hard to manage a warehouse alone? Hiring professionals can reduce the work you have to do. This investment will return to you many times over.

Need help with your warehouse operations? If so, contact us now to find out more about the services we offer. We can handle warehouse management while you focus on growing your core business.

.png)

.png)